Common Mistakes in Zirconia Usage: A Professional's Guide_copy20230616

Welcome to our latest newsletter, where we delve into the crucial topic of precautions and common mistakes to avoid when milling teeth with dental zirconia designs. As dental technology advances, zirconia has emerged as a popular choice for its remarkable strength, aesthetics, and biocompatibility. However, ensuring successful outcomes requires attention to detail and adherence to best practices. Let's explore some key points to consider:

▼1. Material Selection, Case Planning and Design

Choosing the right zirconia material is paramount. Consider factors such as translucency, strength, and shade matching to ensure the most suitable option for each case.

Thorough case planning and meticulous design are essential. Utilize intraoral scanners and CAD/CAM software to accurately capture the patient's oral anatomy and create precise virtual models. Pay careful attention to occlusion, margin placement, and restoration thickness to avoid potential complications during the milling process.

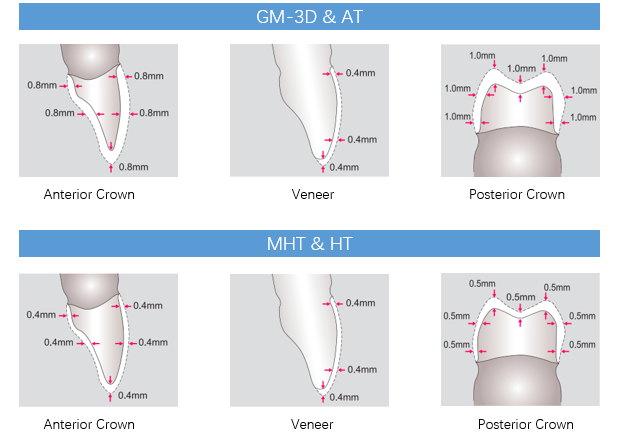

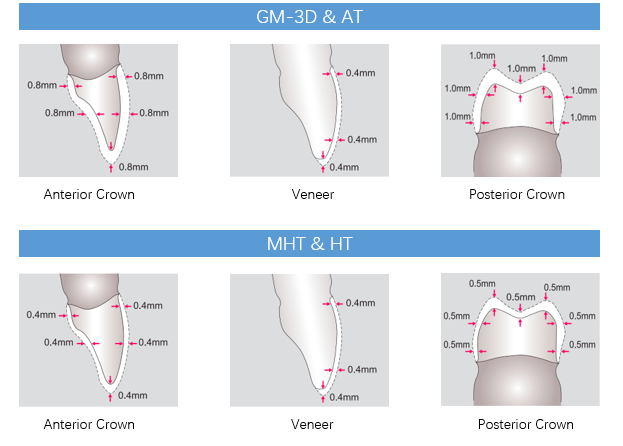

Wall thickness for single crown:

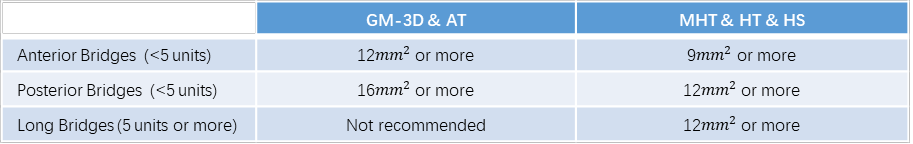

Connector design for bridges

The connector design requirements for dental bridges are listed in the chart below:

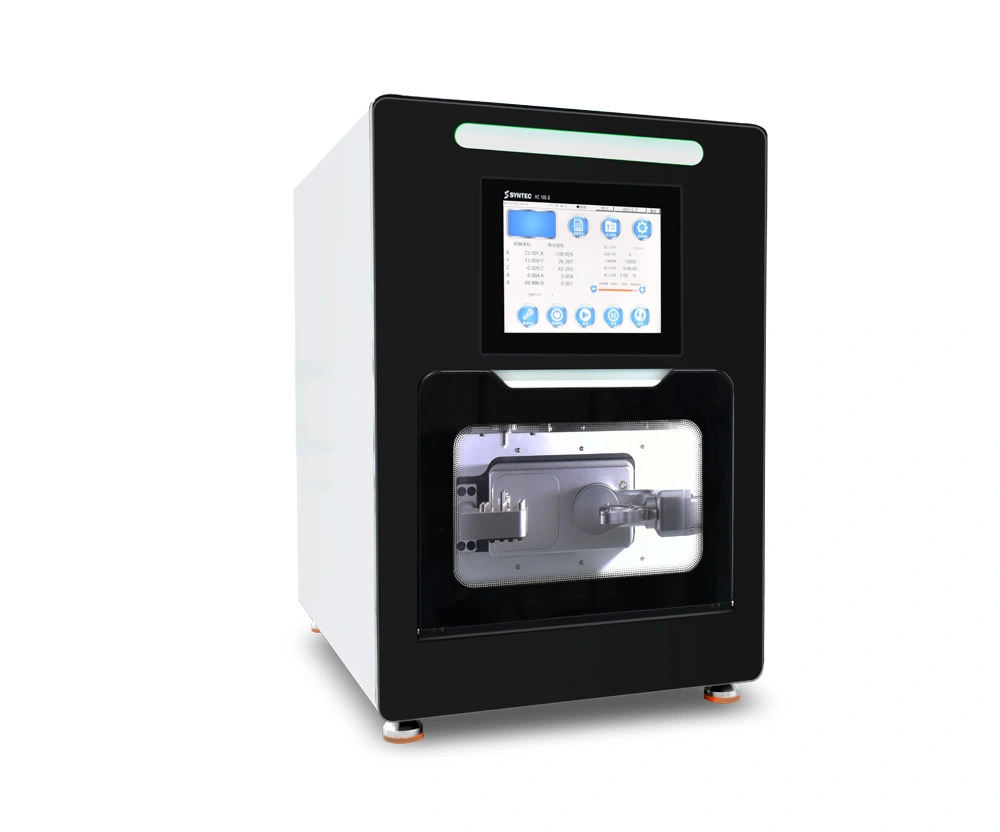

▼2. Milling

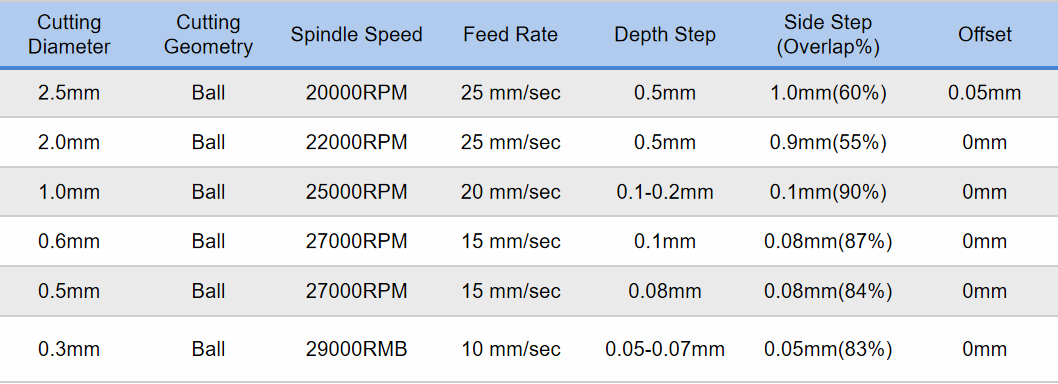

Tool Selection and Maintenance & Milling Parameters:

Regularly inspect and clean the milling tools to prevent buildup of debris and ensure their longevity.

Setting the correct milling parameters is essential for precise and efficient milling. Pay attention to spindle speed, feed rate, and tool path strategies. Adjusting these parameters based on the specific zirconia material and restoration design will help achieve accurate results while minimizing tool wear.

▼3. Sintering

During the sintering process, we found a large number of mechanics making various errors and mistakes. The following are the operational errors we have found that are very likely to cause problems in the sintering of restorations.

No trimming of the restoration before sintering:

Many technicians do not trim and clean the restoration before sintering. This can affect the sintering results.

Neglecting Sintering Guidelines:

Zirconia requires proper sintering to achieve its full strength and translucency. Adhere to the sintering guidelines offered by dental material manufacturers, including temperature, time, and cooling rates, to ensure optimal material properties. Do not sinter multiple brands/multiple types of zirconia, under the same sintering curve. This will not save you time and will only result in a failed restoration.

Overcrowding the Sintering Furnace:

Overcrowding the sintering furnace can impede proper heat distribution, leading to uneven sintering and compromised restoration quality. Maintain adequate spacing between restorations and avoid overcrowding to ensure uniform heat distribution.

Premature Removal from the Furnace:

Removing restorations from the sintering furnace too early can lead to thermal shock and potential fractures. Allow adequate cooling time before handling or transferring the restorations to the post-processing stage.

Sintering zirconia long bridges:

Requires the design of a reinforced band and standing sintering.

English

English  日本語

日本語  français

français  Deutsch

Deutsch  Español

Español  русский

русский  العربية

العربية