Digital Print Denture

-

Digital Scanning

By using HUGE intraoral scanners, this step provides a detailed 3D model of the patient's mouth, including the shape of the gums, teeth, and other oral structures.

Learn More About the Products:

-

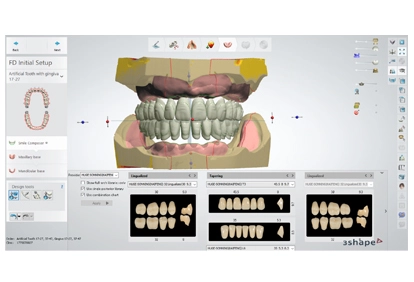

CAD Process

Once the digital scan is obtained, dental professionals use specialized CAD software to design the dentures. The software allows for precise adjustments to ensure proper fit and aesthetics. HUGE denture teeth lines all have denture tooth libraries now.

-

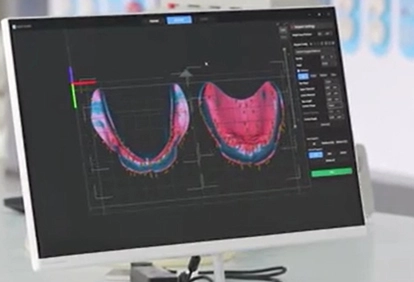

3D Printing Preparationc

Once the digital design is finalized, it is prepared for 3D printing. This involves converting the design into a format compatible with the 3D printer and adjusting the layouts.

-

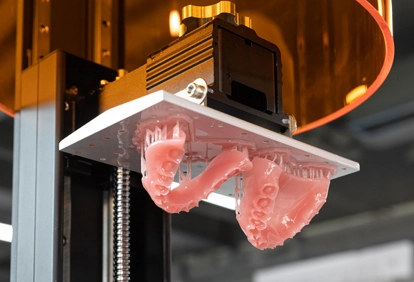

3D Printing the Denture Base

The prepared digital design is sent to a compatible 3D printer, which then fabricates the denture layer by layer using the denture base printing resin, NOBIL-3D 3D printer is capable of producing intricate details with precision, ensuring a customized fit and natural appearance.

Learn More About the Products:

-

Teeth Preparing

Based on the denture tooth libraries you've chosen, you can choose to 3D print the teeth or use prefabricated teeth. Prefabricated teeth usually provides higher precision and natural vividness.

Learn More About the Products:

-

Cementing

Once the printing is complete, it's suggested to use self-curing resin as bonding material for bonding the teeth in the denture bases. According to test, it's time-saving, cheaper and easier to clean.

Learn More About the Products:

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español русский

русский português

português العربية

العربية